Process optimisation for loading and unloading inland waterway vessels and freight wagons: that was the clear requirement for a new 2,600 m2 logistics hall at Bayernhafen Regensburg. The requirement was met with the help of a sliding roof that can be opened towards the harbour side so that the harbour crane can reach directly into the hall. The Tecdos-Pi-Gamma 2-in-1 chain drive system from RUD Ketten Rieger & Dietz GmbH u. Co. KG, based in Aalen, Baden-Württemberg, acts as the ‘open sesame’. Developed for horizontal and vertical applications with a chain deflection of 90° to 180°, the drive reliably opens and closes the 400 m2 section of the roof, withstanding the high dynamic forces acting on the sliding roof element, such as wind and snow loads.

Optimised handling processes in the port

Bauer Resources GmbH, based in Schrobenhausen, has been operating the new hall since the beginning of 2020. It is a full-service provider in the fields of water, environment and mineral resources. Every year, up to 85,000 tonnes of non-hazardous and hazardous mineral waste generated during demolition work or earth excavation are temporarily stored and handled in the new hall. Transhipment onto ships and wagons is particularly easy and quick: ‘Because the roof can be moved towards the harbour basin and the harbour crane can thus reach directly into the open hall, we save twice: unnecessary travel and, of course, time,’ explains Ulrich Morgenstern, Head of Waste Disposal at Bauer Resources GmbH.

2-in-1 chain drive system for moving the hall roof

The sliding roof of the logistics hall in Regensburg is a top reference for RUD's Tecdos Pi Gamma drive system. It was specially developed for vertical and horizontal applications and has a chain deflection between 90° and 180°. The system is based on a high-performance round link chain, also from RUD. This runs over a drive shaft that is free of additional forces. Thanks to its simple design, the drive system is easy to install and maintain. It is particularly force-resistant, durable and corrosion-resistant, making it perfect for outdoor use.

More force: from six to 140 kilonewtons

"Until now, we had been working with relatively small forces of six to twelve kilonewtons. With the hall system in the port of Regensburg, however, we are talking about 140 kilonewtons, which is a huge leap. The chain of the drive system also has a diameter three to four times larger than what we usually install," says Emanuele Frisi, Business Development Manager for the Tecdos product group at RUD, explaining the special nature of the requirement. In the logistics hall at Bayernhafen Regensburg, the drive system consists of four Pi-Gamma pocket wheel blocks, two strands of Tecdos Premium round link chain and four Tecdos end fastenings in parallel.

The main reason for the increased forces and thicker chains is the prevailing wind conditions in the port. With a hall area of over 2,600 m2 and a height of 13 m, wind and snow exert great dynamic forces on the logistics hall – especially on the roof, which covers an area of over 400 m2. For this reason, a type of motor brake was also installed to secure the roof against unwanted movement caused by wind. Shortly after commissioning, the logistics hall, including its sliding roof, successfully withstood Hurricane Sabine, which swept through the Regensburg district in February with winds of over 100 km/h in some places.

Largest application for sliding hall roofs to date

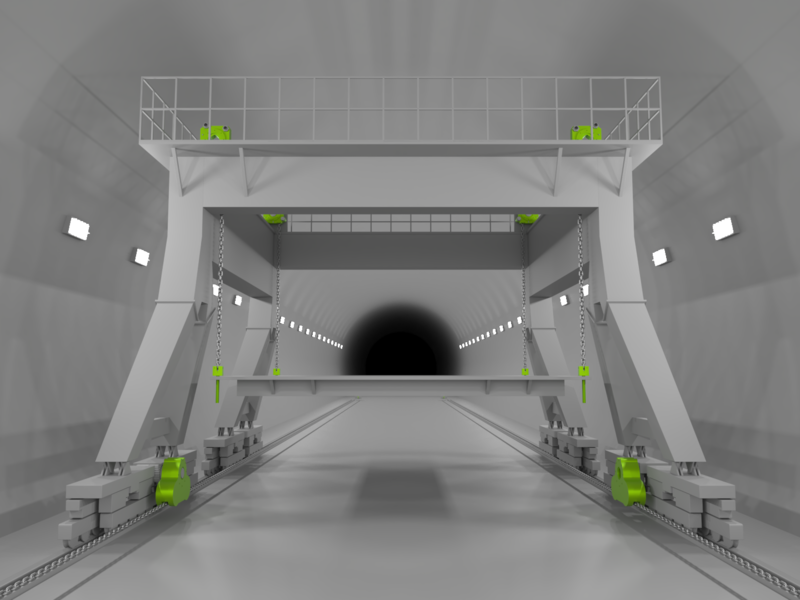

The drive system was calculated and designed by RMS GmbH from Wesel, North Rhine-Westphalia, which also took on the project planning for the logistics hall. Since 2015, the specialist has been relying on Tecdos-Pi-Gamma from RUD for its Lüra sliding roof halls. "Together with RUD, we have already built several openable halls. But the hall in Regensburg harbour is by far the largest and highest. The fact that we are moving a membrane-covered roof in this project is also a first," emphasises Kai Kubasch from the Project Management and Technology department at RMS GmbH. RMS also supplied the Lüra steel partition walls, which serve as the supporting structure for the logistics hall and fulfil another important purpose: The partition walls prevent the tightly bound waste materials from escaping. They were therefore firmly welded in the base area.

Membrane-covered roof without intermediate supports

The roof of the 74 m long and 36 m wide logistics hall consists of a hot-dip galvanised steel truss construction and a PVC membrane covering. It was planned, manufactured and assembled by Modular Hallensysteme GmbH, based in Senftenbach, Austria, with a branch in Passau. Designed as a gable hall, the roof spans very large areas – without any intermediate supports. Moving and shifting a 36 m roof is a special challenge that RUD, RMS and Modular have mastered here. This requires very special expertise and good project planning by all parties involved," emphasises Reinhold Kammerer, managing partner of Modular Hallensystem GmbH. For Modular, this was the first collaboration with RUD as a supplier and project partner.

A solution for every drive requirement

As a development and project partner, RUD supports projects such as the one in Regensburg right from the conception phase and gives designers access to the data. "We have the engineering expertise and can therefore meet almost any drive requirement with our Tecdos standard components. We combine them in such a way that we can also cover particularly large ranges,‘ emphasises Emanuele Frisi. In concrete terms, this means that 140 kilonewtons is by no means the end of the line. ’We can offer even stronger chains and even greater forces," Frisi continues.

Further information is available at www.rud.com.