The rock salt mine and Borth salt works are located in Rheinberg, around 60 kilometers from Düsseldorf. Between 7,000 and 8,000 tons of salt are extracted and processed there every day. The plant is operated by K+S, Europe's largest salt producer. The salt extracted from the mine is first stored temporarily before being used for purposes such as road salt. Borth has a storage capacity of more than a quarter of a million tons of salt: 180,000 tons in underground bunkers and around 70,000 tons in a warehouse. It is here, in the warehouse, that a drive solution from RUD ensures trouble-free hall feeding with salt.

A mobile belt stacker has been optimized and now runs without failure and with low maintenance thanks to the robust RUD Tecdos round steel chain and the innovative RUD Tecdos Omega Drive drive system. The chain and drive were integrated into the existing steel structure. The specialists from the RUD Group, RUD System GmbH, Herfurth & Engelke Förderanlagen GmbH, and RUD Ketten Rieger & Dietz GmbH u. Co. KG worked closely together on the conversion solution.

RUD Tecdos: the optimal solution for trouble-free drive in the salt warehouse

“The round steel chain in combination with the Tecdos drive is the optimal solution for us,” concludes Alexander Gils. He has been working for K+S at the Borth site since 2013, where he is responsible for maintenance and conversion measures on the conveyor systems as a production engineer in the above-ground area. "Previously, our mobile belt stacker was driven directly by the wheels via a gear motor and a roller chain. However, with the salt and moisture in the unheated storage hall, the wheels on the running rails kept slipping or jamming. At least once a week, the system failed and an employee had to pull the belt stacker using a chain hoist. A conversion of the system was inevitable," says Alexander Gils, describing the problem.

Approximately 70,000 tons of salt can be temporarily stored in the warehouse in Borth. The belt conveyor system is located at a height of 20.7 m and has a travel distance of approximately 70 m. With a conveying capacity of 500 t/h, it handles around 1 million tons of salt per year, which corresponds to around 37,000 truckloads. High plant availability is therefore essential. For optimized process reliability, the new drive system for the belt stacker had to be particularly resistant to salt and moisture. Alexander Gils found what he was looking for at RUD and its Tecdos products.

Salt and moisture: no problem for the Tecdos drive system

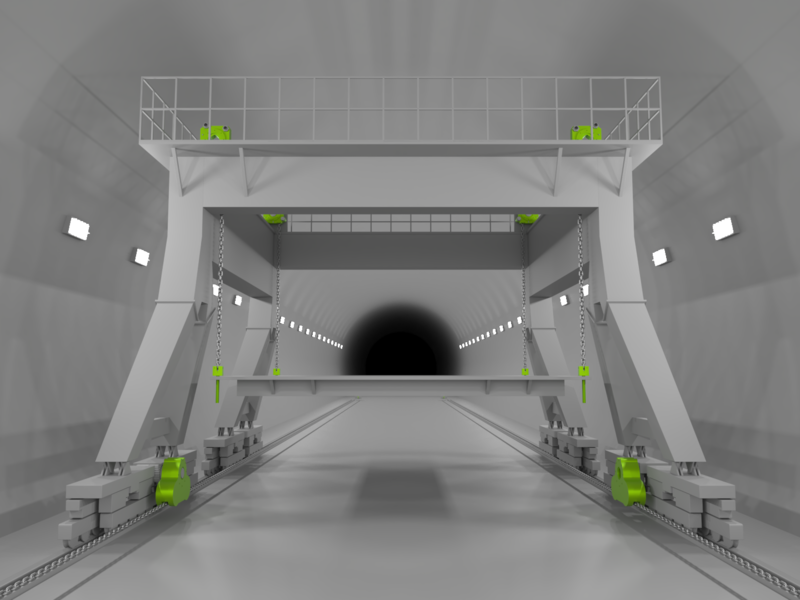

The principle behind the Tecdos drive system from RUD, which is used on the conveyor belt system in Borth, is as simple as it is revolutionary: the Tecdos Omega Drive is attached to the SEW motor of the system and runs along the entire travel distance of around 70 m on the horizontally tensioned Tecdos round steel chain. This is how it moves the belt conveyor back and forth. The RUD divisions worked closely together on the design and layout of the components: The team at RUD System GmbH coordinated and led the project, created the manufacturing and assembly documents, and purchased the components. The specialists at RUD Ketten, on the other hand, were responsible for the design and manufacture of the chain components. Herfurth & Engelke Förderanlagen GmbH took over the production and assembly of the new system.

"Compared to other types of drives, such as rack and pinion drives, spindle drives, or roller chains, our Tecdos system is resistant to aggressive media and harsh weather conditions. It is particularly well suited for use in salt storage facilities. This is because damp fine salt is slippery, causing wheels to lose grip and slip. However, the Tecdos Omega Drive in combination with the round steel chain continues to run," explains Managing Director René Heimlich, who is responsible for project coordination, design, and component purchasing at RUD System GmbH.

Driving at lofty heights

One challenge in designing the conversion was the limited space and the statics at a height of 20.7 m. “The motto was: as big as necessary, as small as possible,” emphasizes Alexander Gils. For the drive, RUD chose its second-smallest drive from the Tecdos Omega Drive series, the Omega Tec 12 with 12 kN pulling force. It scores with its compact dimensions of 280 mm x 102 mm x 250 mm (L x W x H) and a dead weight of 22 kg.

The chain on the belt stacker is a RUD Tecdos Premium round steel chain made of case-hardened steel. “We deliberately chose not to use a stainless round steel chain. On the one hand, our case-hardened round steel chain is more durable and continues to function despite corrosion. On the other hand, we would not have been able to maintain the compact dimensions otherwise,” explains Heribert Herzog, application engineer at RUD Ketten and responsible for the design of the chain drive.

Everything from a single source: from components to steel construction

The height at which the system is installed in the warehouse was also a challenge for the professionals at Herfurth & Engelke. "We had three fitters in harnesses up there at a height of around 20 meters. In terms of occupational safety, this is a bit more demanding and also takes more time to install. But everything worked out perfectly," explains Olaf Uminski, Managing Director of Herfurth & Engelke Förderanlagen GmbH, which is also part of the RUD Group. In addition to installing the new drive system, the specialists for the conversion of existing plants also took on the manufacture of consoles, operating platforms, and steel construction components.

The conversion and commissioning of the optimized belt stacker took place during an annual turnaround at the K+S plant in Borth. The conversion was installed and put into operation within a week.

Wide range of applications for RUD Tecdos drive systems

“The RUD solution is simply ideal for our application and I would recommend it without reservation,” emphasizes Alexander Gils from K+S in Borth. In addition to salt works, the robust RUD Tecdos drive systems are also suitable for use in other industries. “From the automotive industry to maritime applications, RUD Tecdos drives and chains are used wherever something needs to be moved or transported,” says Tobias Rathgeb from the sales team at RUD H&E GmbH.