140,000 m3 of excavated material, 22,000 m3 of concrete used, around 2,500 tonnes of reinforcement and 25,000 tonnes of armour stone: the replacement construction of the Danzermühl hydroelectric power plant in Laakirchen (Upper Austria) was and remains a truly mammoth project. The client, Heinzel Energy, invested €41 million and two and a half years of construction time before the new power plant on the Traun river went into operation in 2019. Now, 120 m³ of water flows through the two turbines every minute, generating 44.8 GWh of electricity. This corresponds to the annual electricity needs of a good 10,000 households. Excess river water is retained by a weir system, and floating debris by a 240 m² rake. To ensure that the weir and power plant can operate efficiently, the rake area must be kept clean. This is achieved by a special rake cleaning system from Braun Maschinenfabrik. It is powered by the innovative Tecdos Omega Drive chain drive system from RUD.

The Danzermühl hydroelectric power plant has been located on the Traun River in Laakirchen since 1880. Over the decades, it has been continuously modernised, adapted and expanded until the decision was made in 2014 to replace it with a new building. ‘We wanted to increase electricity yield, optimise flood protection and also improve the habitat for fish and other organisms in the Traun,’ explains Christian Hufnagel, project manager at Kraftwerk Laakirchen GmbH. ‘Renovating the old power plant would not have made sense, either economically or ecologically. That's why we decided to build a completely new replacement.’

New weir system with a 240 m2 screen

As part of this, a new, fully automatic weir system was also built to retain the water from the Traun river for the power plant. It consists of two weir fields with two weir flaps, each 16 m wide and 4.5 m high, and a bottom outlet field. This is equipped with a segment closure with an attachment flap. A horizontal fine screen with a bar spacing of 30 or 45 mm and an area of 240 m2 keeps out floating debris.

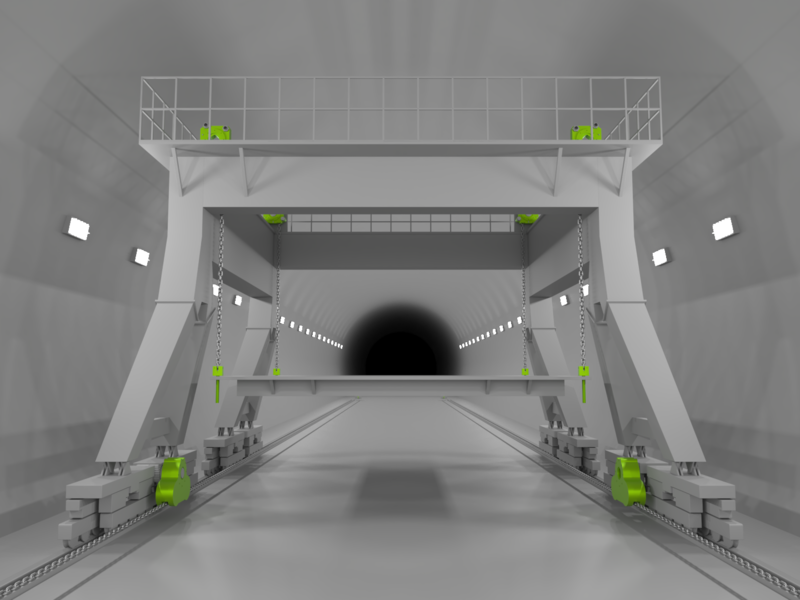

Horizontal screen cleaning system saves disposal costs

For efficient operation of the weir system and the power plant, the screen must be cleared of debris as needed. This job is performed by a screen cleaning system. Here, too, Heinzel Energy has broken new ground and is now using a horizontal screen cleaning system with a cleaning depth of 8.1 metres instead of a vertical one. The horizontal system has two advantages: it has as little impact on nature as possible and the operator saves on disposal costs. Unlike vertical rake cleaners, which remove debris from the water, the biomass is transported downstream via the weir system and thus remains in the river.

The rake cleaning system comes from Braun Maschinenfabrik GmbH, based in Vöcklabruck, also in Upper Austria, just under 25 kilometres from the Danzermühl hydroelectric power station. The company also supplied all the steel hydraulic structures for the replacement construction. "The rake cleaner in Laakirchen is the largest of its kind we have built to date and is a genuine new development. For example, we completely redesigned the chassis,‘ emphasises Robert Konrad, Head of Steel Hydraulic Engineering at Braun Maschinenfabrik GmbH. This is because conventional drives such as racks and ropes were out of the question due to the weather conditions and the length of the screen. ’We needed a different solution," Konrad continues.

Innovative drive system: Tecdos Omega Drive

This came from RUD Ketten Rieger & Dietz GmbH u. Co. KG, based in Aalen, Baden-Württemberg (Germany). As a development partner for Braun's innovative rake cleaning system, it supplied its innovative Tecdos Omega Drive drive system for rotary and linear movements. The installed drive has a maximum pulling force of 6.5 tonnes or 65 kN and a dead weight of 297 kg. In the case of the weir system at the Danzermühl power plant, the system operates at two speeds: 14 m per minute at full load and 28 m per minute without load.

The Tecdos Omega Drive is based on a high-performance round link chain, also from RUD. This makes the drive system particularly robust and resistant to dirt, sand, water and ice. This is an advantage over other alternatives such as rope or rack and pinion drives. "Our Tecdos Omega Drive is used wherever conditions are difficult: in dirty environments and under adverse weather conditions. Even frequent or irregular use is no problem for our drive; in both cases, the Tecdos Omega Drive runs reliably. This demonstrates the advantages of the case-hardened, highly wear-resistant Tecdos round link chain," explains Heribert Herzog, application engineer at RUD.

Quick installation and low maintenance

The drive is also particularly compact. The ‘Omega 65’ model, which is also used in Laakirchen, is 468 mm high, 649 mm long and 296 mm wide. This compactness also makes installation much easier – unlike other types of drives. "With rack and pinion drives, for example, the racks have to be bolted to a stable base at short intervals to prevent deformation. With a travel distance of almost 50 metres, as is the case with the rake cleaning system at the Danzermühl power plant, this adds up to quite a lot. The rack and pinion drive not only costs a lot of time and money to install, but is also more prone to maintenance and malfunctions,‘ explains Emanuele Frisi, Business Development Manager in the Conveying & Driving division at RUD. Heribert Herzog adds: ’We are flexible when it comes to travel distance: theoretically, we can achieve anything from two to a few hundred metres."

Removes even thread algae

The rake cleaning system in Laakirchen is in daily use and therefore cannot afford any malfunctions. ‘Even in autumn, when there is little flotsam in the Traun, the rake cleaner runs on average once a day. In spring, on the other hand, when there is a lot of flotsam in the river, the system is busy clearing it approximately every two hours,’ explains Christian Hufnagel of Kraftwerk Laakirchen GmbH. A particular challenge is the thread algae that appear in the Traun in the spring and summer months and wrap themselves around the rake bars. Braun has therefore developed special tines that can be mounted on the 9 m long rake as required.

From custom-made to series production

This was the first joint project between Braun Maschinenfabrik GmbH and RUD. ‘Everything went perfectly and we hope to have more projects with RUD soon. We have made the newly developed horizontal screen cleaning system with the Tecdos Omega Drive chain drive a standard feature in our product range. From custom-made to series production, so to speak,’ says Konrad, delighted with the result of the collaboration.

RUD also has the solution for sewage treatment plants.

In addition to weir systems, rectangular sewage treatment plants also need efficient and reliable rake cleaning systems. RUD offers innovative solutions for this too, with the two Tecdos drives Omega Drive and Pi-Gamma. As a 2-in-1 complete system, Tecdos Pi-Gamma is particularly suitable for horizontal and vertical applications with a fixed chain deflection of 180 degrees or a flexible deflection of 90 to 18 degrees. The two Tecdos drive systems from RUD are a genuine alternative to conventional friction wheel drives. This is because the latter quickly reach their limits in ice and snow or other contaminants on the travel path. The Tecdos drive systems work in conjunction with the Tecdos round link chain with positive locking, ensuring safe power transmission and reliable operation – regardless of the weather.

About the new Danzermühl power plant:

Since it went into operation in summer 2019, the new Danzermühl hydroelectric power plant has been generating 2.5 times the amount of electricity, namely 44.8 GWh per year. By comparison, the old hydroelectric power plant generated 16.5 GWh annually. Two factors have made this enormous increase possible: firstly, the head was increased from 7 to 9.2 metres by combining the two barrages at Danzermühl and Kohlwehr, which is further downstream. In addition, the design flow rate was increased from 60.1 m3 to 120 m3 per second. This is the maximum amount of water that the two new turbines can use to generate electricity. 100 per cent of the electricity flows to the neighbouring Laakirchen Papier AG, which, like the hydroelectric power plant, is part of the Heinzel Group.

About Heinzel Energy:

Heinzel Energy, operating under the name Heinzel EMACS Energie GmbH, develops projects in the field of renewable energy. These include hydroelectric power plants on the Pöls River in Styria and on the Traun River in Upper Austria, which supply electricity directly to their sister companies Zellstoff Pöls AG and Laakirchen Papierfabrik AG. The company also operates a wind farm in Burgenland on the grounds of Domaine Albrechtsfeld GmbH and has developed a photovoltaic solar field there with over 1,000 collectors. Heinzel Energy has already installed a total of over 5 MWp of PV capacity. In Laakirchen, the company is currently constructing a PV plant with a capacity of 2.6 MWp, which will bring the total number of PV modules installed to over 23,000. Further plants are planned for the coming years.

About Braun Maschinenfabrik:

Since 1848, the Vöcklabruck-based company has been involved in products and machines for processing a wide variety of materials. In 1965, it entered the field of cut-off grinding technology with resin-bonded cutting discs. The pursuit of technological leadership prompted Braun to intensify the further development of tools and innovative cutting and grinding processes. Today, the technology leader's product range includes steel cutting and grinding machines for the steel industry, equipment for hydraulic steel construction, and tailor-made solutions for the dismantling of nuclear and contaminated facilities. With comprehensive support – from conception to revitalisation – Braun supports projects with concepts, machines and associated tools. In-house engineering, automation and implementation guarantee the best quality.